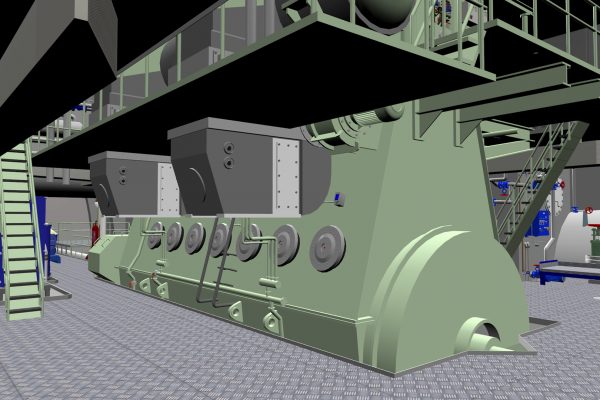

The Low Speed Engine Room Simulator LER3D has been based on typical solutions, being presently used in medium-sized engine rooms (one two-stroke type main engine with fixed pitch propeller).

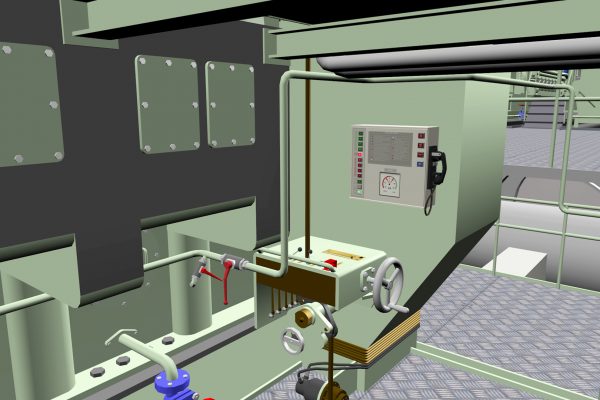

The simulator introduces 3D model of the Engine Room, based on the real equipment. In order to create the impression of working in the real environment, it provides 3D sound which can be listened on 2, 4 or more speakers.

LER3D has been developed to comply with:

- STCW Code: Section A-1/12 and Section B-1/12,

- ISM Code: Section 6 and Section 8.

LER3D is based on an engine room composed of one low-speed diesel engine, three diesel engine generators.

LER3D simulator model includes following systems:

- Fuel System;

- Cooling & Fire System;

- Lubricating System;

- Compressed Air System;

- Power Plant;

- Emergency Generator;

- Steam System;

- Sanitary Water System;

- Bilge System;

- Steering Gear;

- Sewage Treatment Plant;

- Refrigerating System;

- Sanitary Water System;

- Fresh Water Generator;

- Air Conditioning Plant;

- Water Mist System;

- CO2 System;

- Incinerator.

Here is a list of LER3D main features:

- LER3D is a highly realistic simulator for ship’s engine room training which can also be used as a low cost introductory simulator.

- The mathematical model simulates a typical ship’s engine room with one 4-stroke, low speed engines, reduction gear and controllable pitch propeller.

- All vital auxiliary systems have been implemented.

- The user interface includes virtual controls and alarms and creates very realistic environment.

- The 3D virtual reality with active valves, tank level indicators and selected digital gauges enable comfortable engine room operation and monitoring.

- Multichannel digitised sound provides a very realistic ships’ engine room feel. The sound effects include: engine sound correlated with engine speed, the sound of a diesel generator starting and running, open indicator valve sound, alarm and machine telegraph buzzers.

- Emergency procedure training including fire simulations.

The main educational tasks which can be accomplished using LER3D have been listed below:

- Learning ship’s engine room typical operating routines.

- Ship’s engine room operation training. The user will have the possibility to accomplish any operational task starting from different setups, both pre-prepared and saved by a user.

- Corrective action learning when faults occur. Different faults can be simulated and mixed in the run-time or loaded from disk.

To meet the requirements:

Engine Room Simulator has been developed to comply with STCW Code:

- Section A-1/12 and Section B-1/12

- ISM Code: Section 6 and Section 8